Fluidized Bed Dryer Uses

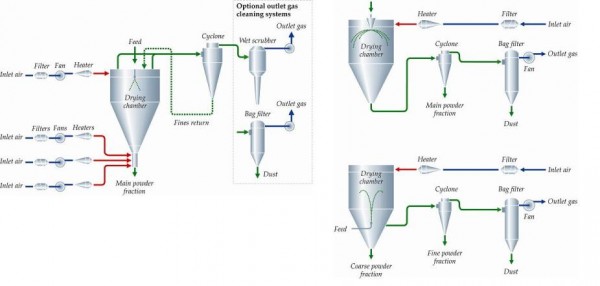

Fluidized beds are also used for efficient bulk drying of materials.

Fluidized bed dryer uses. High thermal efficiency is achieved when the thermal energy is supplied by internal heat exchanger. The self cleansing action of the fluidized bed prevents the heat exchangers from becoming fouled and losing efficiency. With the material in a fluidized state there are no hot spots. Fluid bed drying aveka s food grade and industrial fluidized bed drying is an efficient way to dry particles larger than 50 microns.

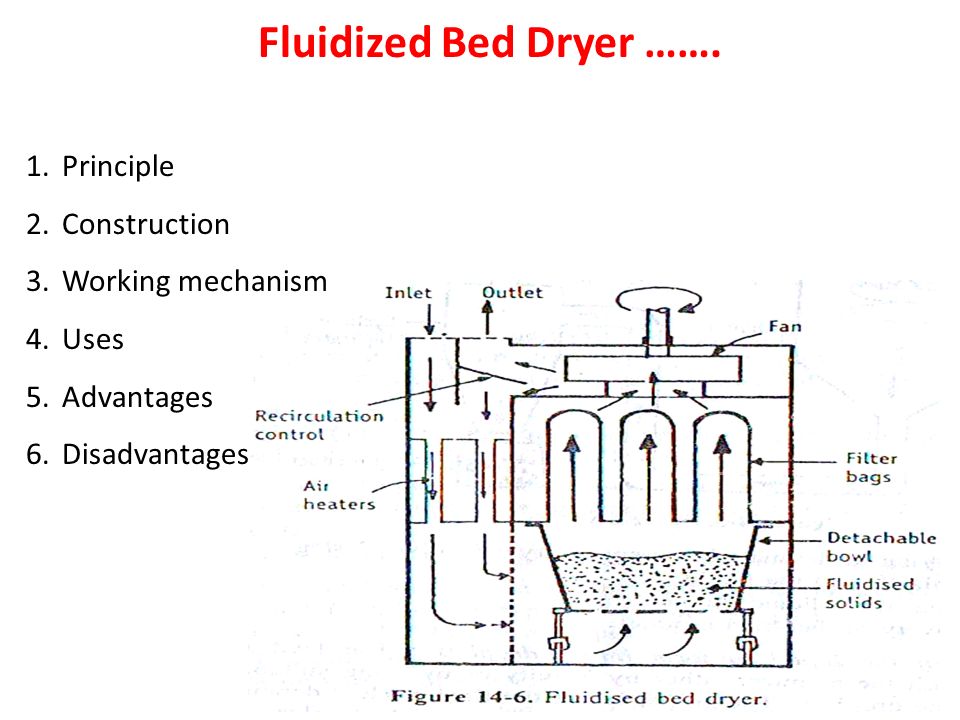

Pilotech lab scale fluid bed dryer yc 310 laboratory spray granulator is a benchtop granulator with a minimum sample throughput of 100 grams. The equipment works on a principle of fluidization of the feed materials. A fluidized bed dryer is widely used in the granulation area of pharmaceutical manufacturing. Yc 310 laboratory spray granulator is suitable for pharmaceutical food ceramics biology chemicals materials and other industries.

Fluidized bed dryer also called fluid bed dryer is a kind of equipment used extensively in the pharmaceutical industries to reduce the moisture content of pharmaceutical powder and granules. The pot body can be changed to suit different processing capacities. Fluidized bed dryer fluidized bed dryer achieves faster drying rates with the drying time ranging from 20 minutes to 40 minutes. Fluidized bed dryer fbd is well known and widely used equipment in granulation area of pharmaceutical manufacturing.

Fluid bed dryer has a high drying rate therefore the material gets dried very quickly. Hence the bed is said to be fluidized and the particles are suspended in the fluid. By using a fluid bed dryer the moisture content of pharmaceutical granules and powder can be decreased in a consistent manner. It is used in the granulation process for drying the material to get desired moisture content in the tablet formulation granules required for perfect compression of tablets.

The principle of fluidized bed dryer. Some of them are as follows. There are various advantages of fluid bed dryer in pharmaceutical industries. Wet cake is fed directly into the fluid bed without the need for pre conditioning the wet cake or recycling any dried biosolids.

Fluidized bed technology in dryers increases efficiency by allowing for the entire surface of the drying material to be suspended and therefore exposed to the air. Granulation is a technique to dry the material in order to get the desired moisture content so that the manufactured medicines pellets are perfectly compressed. It enhances the product s properties i e.